SERVICE

Vehicle Engineering CAD/CAE

Advancing towards to a more sustainable future.

CAD – Design solutions

Sub-systems/Components CAD Development:

HV Battery, OBC, DCDC, PDU.

Vehicle Module Development Support in CAD Systems:

BIW, D&C, CHS, INT, EXT, PWT, EE Wiring Harness, Pipeline Layout

CAD Data Migration

2D to 3D CAD Conversion

Drawing Documentation Creation

2D to 3D CAD Conversion

Reverse Engineering 3D Scan Data Convert to CAD

Automation Tool Development for CAD Software (Macros, RPA, VBA, Python) to reduce processing time

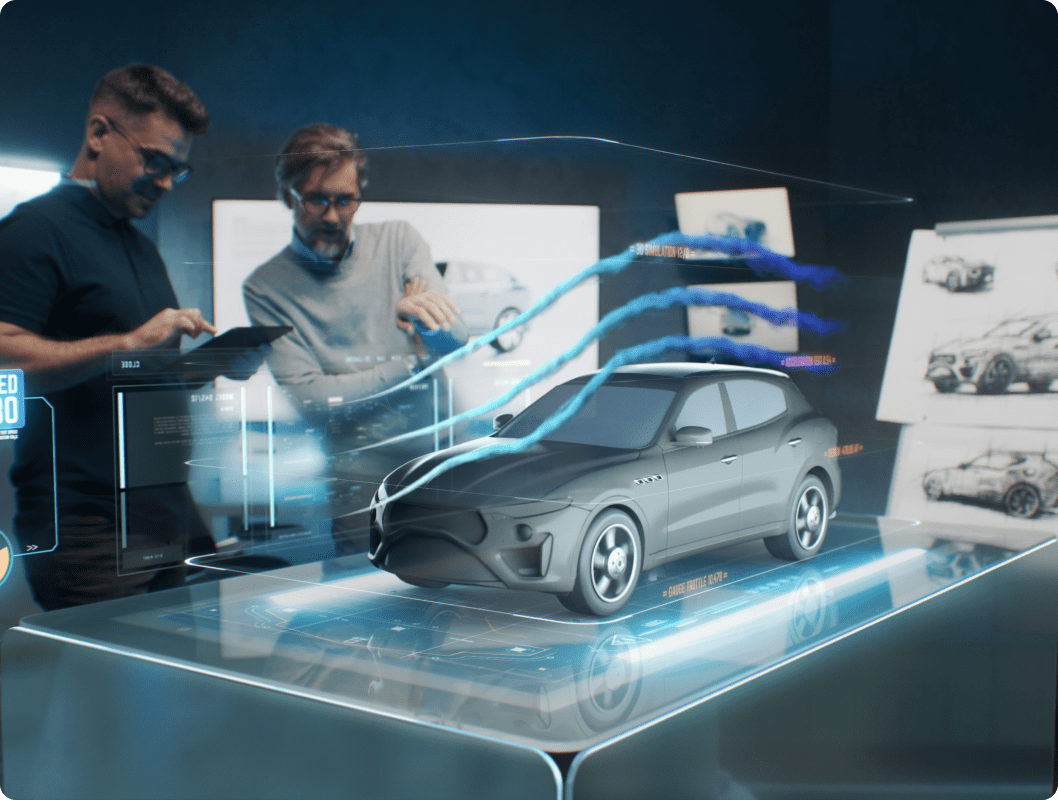

CAE – Virtual development solutions

Body:

Global & Local Modes, Torsional & Bending Stiffness, Local Stiffness, Operational Strength and Durability, Misuse Events, Welding Analysis

Door & Closures:

Oil Canning & Denting, Stiffness, Sag & Set, Overstretch, Slam/Over slam, Door Intrusion, Aerodynamic Load

Chassis:

Hardpoints Definition, Modal Analysis, Stiffness, Operational Strength, Durability, Misuse Events, K&C, Ride & Handling, Topology Optimization

Exterior:

Modal Analysis, Stiffness, Durability, Oil Canning & Denting, Thermal Load

Interior:

IP, CC, DP Development, Interior Head Impact, Seat Development

NVH:

Modal Analysis, Frequency Response, Dynamic Stiffness, Mode Map, Vibration Transfer Function, Noise Transfer Function

Stiffness, Strength & Durability:

Global & Local Stiffness, Fatigue Load, Misuse Events, Welding Analysis, Thermal Load

Safety Development for Global Markets US, EU, Asia according to regulatory requirements, consumer tests and insurance requirements

Frontal, Side, Rear Impact, Roof Crush, Door Intrusion, Low Speed Impact

Occupant Safety, Belted & Unbelted, Interior Head Impact, Knee Impact, Whiplash

Vulnerable Road Users (VRU) Protection

HV System & HV Battery Safety

Material Cards Development

Vehicle Dynamic:

K&C, Ride & Handling, Load Generation, Flexible Bodies

Aerodynamic/Thermal Management:

Aerodynamic Drag Reduction/Wind Tunnel Validation, Aeroacoustics, HVAC/Cabin Comfort, Water Wading, Cooling/Heating

Energy Management (1D System Simulation):

Range NEDC, WLTP, EPA, Acceleration, Top Speed

Component Development:

HV Battery Structural & Thermal, OBC, PDU, DCDC

Optimization: Topology Optimization, MDO, Weight reduction, DOE, Sensitivity study

Automation Tool Development to reduce processing time (Macros, RPA, VBA, Python)

Simulation/Test Correlation & Validation